Pipeline Safety Metrics

Colorado’s Pipeline Safety

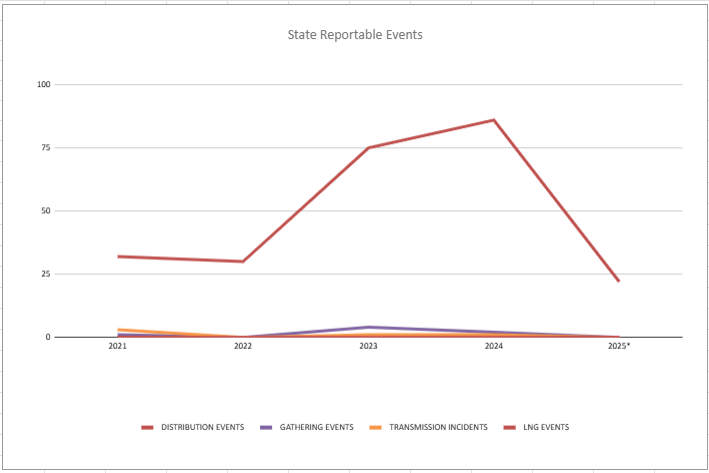

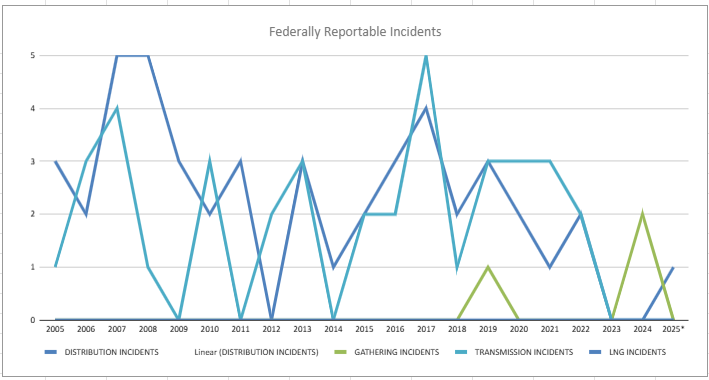

As of April 2025, Colorado’s Pipeline Safety Program regulates pipeline safety on 58,900 miles of gas distribution lines, 2,800 miles of intrastate gas transmission lines, and 5,300 miles of gas gathering lines. In 2024, there were 2 reportable incidents under the agency’s purview.

Click on the graphs to the right to view larger files.

Leak Detection Data

The leak data provided in the table below is provided as a requirement of 4 CCR 723 Part 11 Section 11100(f). Beginning March 31, 2025 and annually on March 31 of each year thereafter, each jurisdictional operator submits an annual leak report to the PUC. The Pipeline Safety Program reviews and aggregates the data to provide the information provided below. The information provides a total of all operators that are regulated by the PUC. The causes of the leaks is explained with the definitions below. The total volume of leaks provided is based on the data provided by 49 operators that operate approximately 67,000 miles of state regulated gas pipelines.

| Year | Total Number of Leaks Due to Corrosion Failure | Total Number of Leaks Due to Natural Force Damage | Total Number of Leaks Due to Excavation Damage | Total Number of Leaks Due to Other outside force Damage | Total Number of Leaks Due to Pipe, Weld, or Joint Failure | Total Number of Leaks Due to Equipment Failure | Total Number of Leaks Due to Incorrect Operations | Total Number of Leaks Due to Other Causes | Volume of Leaks by MMscf (million standard cubic feet) |

|---|---|---|---|---|---|---|---|---|---|

| 2024 | 734 | 591 | 1324 | 364 | 1657 | 8708 | 232 | 1336 | 327 |

Definitions

Leak - An unintentional escape of gas from a pipeline. Test failures are not included.

Corrosion Failure - Leak caused by galvanic, atmospheric, stray current, microbiological, or other corrosive action. A corrosion release or failure is not limited to a hole in the pipe or other piece of equipment. If the bonnet or packing gland on a valve or flange on piping deteriorates or becomes loose and leaks due to corrosion and failure of bolts, it is classified as Corrosion.

Natural Force Damage - Leak caused by outside forces attributable to causes NOT involving humans, such as earth movement, earthquakes, landslides, subsidence, heavy rains/floods, lightning, temperature, thermal stress, frozen components, high winds (Including damage caused by impact from objects blown by wind), or other similar natural causes. Lightning includes both damage and/or fire caused by a direct lighting strike and damage and/or fire as a secondary effect from a lightning strike in the area. An example of such a secondary effect would be a forest fire started by lightning that results in damage to a gas distribution system asset which results in an incident.

Excavation Damage - Leak resulting directly from excavation damage by operator's personnel (oftentimes referred to as “first party” excavation damage) or by the operator’s contractor (oftentimes referred to as “second party” excavation damage) or by people or contractors not associated with the operator (oftentimes referred to as “third party” excavation damage). Also, this section includes a release or failure determined to have resulted from previous damage due to excavation activity. For damage from outside forces OTHER than excavation which results in a release, use Natural Force Damage or Other Outside Force, as appropriate.

Other outside force Damage - Leak resulting from outside force damage, other than excavation damage or natural forces such as:

- Nearby Industrial, Man-made or Other Fire/Explosion as Primary Cause of Incident (unless the fire was caused by natural forces, in which case the leak should be classified Natural Forces. Forest fires that are caused by human activity and result in a release should be reported as Other Outside Force),

- Damage by Car, Truck, or Other Motorized Vehicle/Equipment NOT Engaged in Excavation. Other motorized vehicles/equipment includes tractors, mowers, backhoes, bulldozers and other tracked vehicles, and heavy equipment that can move. Leaks resulting from vehicular traffic loading or other contact (except report as “Excavation Damage” if the activity involved digging, drilling, boring, grading, cultivation or similar activities.

- Damage by Boats, Barges, Drilling Rigs, or Other Maritime Equipment or Vessels so long as those activities are not excavation activities. If those activities are excavation activities such as dredging or bank stabilization or renewal, the leak repair should be reported as “Excavation Damage”.

- Previous Mechanical Damage NOT Related to Excavation. A leak caused by damage that occurred at some time prior to the release that was apparently NOT related to excavation activities, and would include prior outside force damage of an unknown nature, prior natural force damage, prior damage from other outside forces, and any other previous mechanical damage other than that which was apparently related to prior excavation. Leaks resulting from previous damage sustained during construction, installation, or fabrication of the pipe, weld, or joint from which the release eventually occurred are to be reported under “Pipe, Weld, or Joint Failure”. Leaks resulting from previous damage sustained as a result of excavation activities should be reported under “Excavation Damage” unless due to corrosion in which case it should be reported as a corrosion leak.

- Intentional Damage. Vandalism means willful or malicious destruction of the operator’s pipeline facility or equipment. This category would include pranks, systematic damage inflicted to harass the operator, motor vehicle damage that was inflicted intentionally, and a variety of other intentional acts.

- Terrorism, per 28 C.F.R. § 0.85 General functions, includes the unlawful use of force and violence against persons or property to intimidate or coerce a government, the civilian population, or any segment thereof, in furtherance of political or social objectives.

- Theft. Theft means damage by any individual or entity, by any mechanism, specifically to steal, or attempt to steal, the transported gas or pipeline equipment. "

Pipe, Weld, or Joint Failure - Leak resulting from a material defect within the pipe, component or joint due to faulty manufacturing procedures, design defects, or in-service stresses such as vibration, fatigue and environmental cracking. Material defect means an inherent flaw in the material or weld that occurred in the manufacture or at a point prior to construction, fabrication or installation. Design defect means an aspect inherent in a component to which a subsequent failure has been attributed that is not associated with errors in installation, i.e., is not a construction defect. This could include, for example, errors in engineering design. Fitting means a device, usually metal, for joining lengths of pipe into various piping systems. It includes couplings, ells, tees, crosses, reducers, unions, caps and plugs. Any leak that is associated with a component or process that joins pipe such as threaded connections, flanges, mechanical couplings, welds, and pipe fusions that leak as a result from poor construction should be classified as “Incorrect Operation”. Leaks resulting from failure of original sound material from force applied during construction that caused a dent, gouge, excessive stress, or other defect, including leaks due to faulty wrinkle bends, faulty field welds, and damage sustained in transportation to the construction or fabrication site that eventually resulted in a leak, should be reported as “Pipe, Weld or Joint Failure”.

Equipment Failure - Leak caused by malfunctions of control and relief equipment including regulators, valves, meters, compressors, or other instrumentation or functional equipment, Failures may be from threaded components, Flanges, collars, couplings and broken or cracked components, or from O- Ring failures, Gasket failures, seal failures, and failures in packing or similar leaks. Leaks caused by over pressurization resulting from malfunction of control or alarm device; relief valve malfunction: and valves failing to open or close on command; or valves which opened or closed when not commanded to do so. If over pressurization or some other aspect of this incident was caused by incorrect operation, the incident should be reported under “Incorrect Operation.”

Incorrect Operations - Leak resulting from inadequate procedures or safety practices, or failure to follow correct procedures, or other operator error. It includes leaks due to improper valve selection or operation, inadvertent over pressurization, or improper selection or installation of equipment. It includes a leak resulting from the unintentional ignition of the transported gas during a welding or maintenance activity.

Other Causes - Leak resulting from any other cause not attributable to the above causes. A best effort should be made to assign a specific leak cause before choosing the Other cause category. An operator replacing a bare steel pipeline with a history of external corrosion leaks without visual observation of the actual leak, may form a hypothesis based on available information that the leak was caused by external corrosion and assign the Corrosion cause category to the leak.